Slip on flanges are a popular choice in many industrial applications due to their ease of installation, versatility, and cost-effectiveness. They come in various types, each designed to meet specific requirements and conditions. In this article, we’ll explore the different types of slip on flanges and their unique characteristics.

1. Standard Slip On Flanges

Standard slip on flanges are the most commonly used type. They are designed to slip over the end of the pipe and are then welded in place both inside and outside. This provides a secure connection that is suitable for a wide range of applications, from low-pressure systems to more demanding environments.

Key Features:

- Simple installation process

- Versatile and widely used

- Suitable for various pressure ratings

2. Raised Face Slip On Flanges

Raised face slip on flanges feature a small raised section around the bore. This raised area concentrates more pressure on the gasket, which helps achieve a better seal. They are commonly used in high-pressure applications where a strong, leak-proof connection is essential.

Key Features:

- Enhanced sealing capability

- Ideal for high-pressure applications

- Common in oil and gas, petrochemical industries

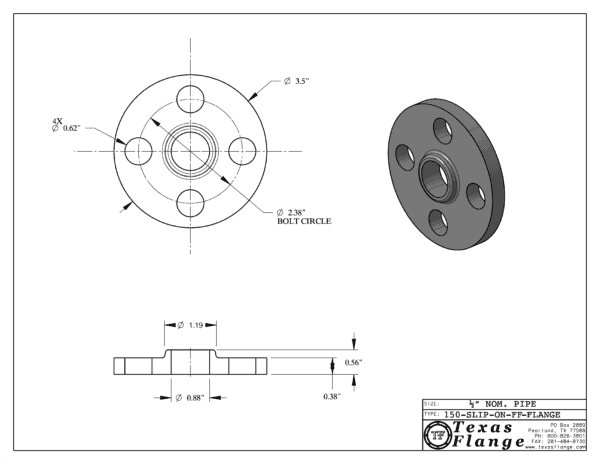

3. Flat Face Slip On Flanges

Flat face slip on flanges have a flat surface and are designed to be used with flat gaskets. They are typically used in systems where the counter flange is also flat, such as cast iron flanges. This type helps to prevent bending moments that could damage the flange.

Key Features:

- Prevents bending moments

- Used with flat gaskets

- Suitable for low-pressure applications

4. RTJ (Ring Type Joint) Slip On Flanges

RTJ slip on flanges feature a groove cut into their face, which holds a metal ring gasket. This design provides a highly secure seal that is ideal for high-pressure and high-temperature applications. RTJ flanges are commonly used in the oil and gas industry.

Key Features:

- High-pressure, high-temperature capability

- Metal ring gasket for a secure seal

- Used in demanding industrial environments

5. Threaded Slip On Flanges

Threaded slip on flanges have a thread inside the flange bore that matches the external thread on the pipe. They are used in applications where welding is not feasible or practical, such as in systems with high levels of explosive materials.

Key Features:

- No welding required

- Easy to install and remove

- Suitable for flammable or explosive environments

6. Lap Joint Slip On Flanges

Lap joint slip on flanges are used with a stub end and are commonly used in systems that require frequent disassembly for inspection and maintenance. They provide a flexible and easy-to-disassemble connection, making them ideal for certain applications.

Key Features:

- Used with a stub end

- Allows for frequent disassembly

- Flexible and easy to remove

Conclusion

Slip on flanges come in various types, each designed to meet specific application requirements. From standard and raised face to RTJ and threaded types, understanding the differences can help you choose the right flange for your needs. Each type offers unique benefits, ensuring a secure, reliable, and cost-effective solution for your piping systems.

For more detailed information and expert advice on slip on flanges, visit Texas Flange.